This website uses cookies to ensure you get the best experience on our website. To read our full cookie policy please click here.

Sympatex: Sustainability Meets Performance

“At Sympatex, we produce 100% recycled and recyclable polyester membranes, which are PTFE- and PFC-free and completely climate neutral.”

When it comes to outerwear, style and function have dominated the rails but not any more; consumers now no longer need to choose between looking good or protecting our planet. As Verena from Sympatex goes on to explain, wearing items that also positively impact our planet are now ruling the slopes.

1) What is the problem with conventional outerwear?

The problem is, as with most fashion in general, it is not sustainable at all. The textile industry is the second dirtiest industry in the world – right after the oil industry – due to its high CO2 emissions, water consumption and use of harmful chemicals. Moreover, at the end of the clothing life cycle, there is also a waste of resources because most of our clothes end up in our trash.

2) How are these problems impacting our environment?

The quantities of raw materials consumed by the fashion industry are astonishing: approximately 100 billion items of clothing and 23 billion pairs of shoes are produced annually. That would not even be so tragic if 97% of this did not come from new raw materials and only a very small proportion from recycled materials. This means that every year vast amounts of raw materials are used for the production of textiles and shoes.

3) Sympatex is seen to be revolutionising the textile market, can you explain how you are doing this?

At Sympatex, we produce 100% recycled and recyclable polyester membranes, which are PTFE- and PFC-free and completely climate neutral. This creates the best possible conditions for a recycling process at the end of the product life cycle. We have also joined forces with market partners to form the European wear2wear consortium in order to close the textile cycle in the functional textile sector as quickly as possible.

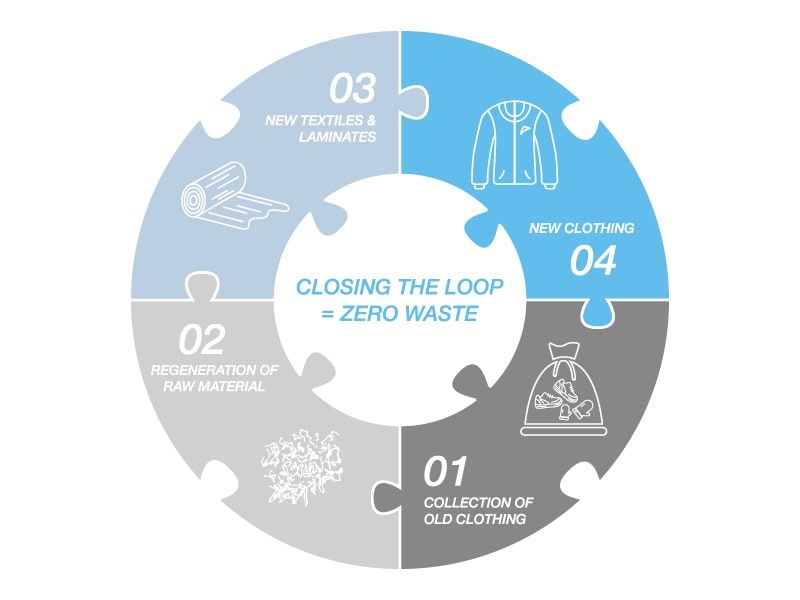

4) What do you mean by ‘closing the textile loop’?

The aim is to create new, high-quality functional textiles from old functional textiles. In addition, Sympatex aims at closing the ecological loop in the functional textile industry by 2030. We are already offering laminates made from used, circularly sourced textile materials since 2020. The goal is that within the next five years at least half of the raw materials required for our functional laminates will come from a circular textile supply chain and will be fully recyclable again – and will be 100% circular by 2030.

5) There are lots of abbreviated and technical words used in the textile world! Can you tell us the ‘Good’, ‘OK’ and ‘Bad’ ones that we should be looking out for?

Often it is not so easy to find the “bad” components in fashion, because they are not labelled. However, one thing that is very important, especially for outdoor clothing, is that there are not toxic PFAS chemicals involved. Therefore, it is good to look for hangtags that say “PTFE-free” and “PFC-free”. Another tip is to pay particular attention to trustworthy seals that guarantee very high ecological and social standards when buying. We recommend IVN Best Standard, Fair Wear Foundation, Bluesign and OEKO-TEX.

6) When it comes to PFCs, why and how are these being phased out?

Let’s first explain the “why”: Anyone who has already dealt with the issue of fluorochemicals and followed in recent months the process referred to under the leadership of the EU will have been relieved to see that, after many years, an attempt is finally being made to reverse the burden of proof of a chemical use that has become known and infamous under the name “eternal chemicals”. This group (PFCs or PFAS) of nearly 5,000 different chemical substances is man-made and so resilient that it will never dissipate in nature. Some of their compounds (which have also been used extensively in the past by the textile industry, both in the form of C8 coatings and in the manufacture of PTFE membranes) have long been shown to be hazardous to human health once released into the environment.

If you haven’t done so already it is highly recommended to watch the feature film “Dark Waters” by Todd Haynes, which exposes the scandal about the production of Teflon® (chemically “polytetrafluoroethylene” – also known in the outdoor industry as PTFE) by the company DuPontTM. The film is not only based on real facts, but it simply leaves one speechless in view of the decades of unscrupulousness with which the fluorochemical industry has put its profit interests before obvious health hazards to the public.

7) Are there alternatives to using PFAs/PFCs and are these as effective?

To put it simply, Yes! PFAS are simply not necessary! We produce long- established alternatives that are sufficiently powerful for almost all applications but also distorts competition. Not only have bold pioneering brands as Vaude and Bleed been relying on fluorochemical-free membranes and PFC-free impregnations for years. Now other renowned brands like Jack Wolfskin, Haglöfs and Mammut have embraced this strategy, too.

8) In 2021 Sympatex were given the B Corp “Best for the World” award. Please can you explain about the work that you were recognised for? Has receiving this incredible accolade impacted your passion and determination going forward?

As one of the first German companies of the textile industry, Sympatex Technologies GmbH has been awarded with the internationally renowned hallmark for above- average corporate governance in the holistic interest of society beyond corporate borders. As our CEO DR. Rüdiger Fox explains “We want to send a signal that we as a commercial enterprise need to recognize our responsibility for the overall social and ecological system and must not abuse it unilaterally for our own interests.” Dr Fox goes on to say “We are only at the beginning of this journey. The certification shows us where we stand right now and where further proactive action is still helpful in order to fulfil our role in society at large”.

9) Can you share some of your brand partners and what positive changes they are making within the textile industry?

We work very close with sustainable brands like Vaude, Bleed, Zanier, Rossignol, Lagoped, Rotauf, Element just to name a few. They are all doing exceptional work within the textile industry. For example, our two brand partners Bleed and Zanier developed the Eco Active Glove, a multifunctional outdoor glove that closes the recycling loop 100%. The brand Zanier is constantly pushing sustainable materials and is the world’s only CO2-neutral glove manufacturer. Moreover, Bleed is one of the first sport and streetwear brands that offers a fully recycled outdoor jacket that has been made completely carbon-neutral, together with climate action consultant ClimatePartner and Sympatex.

10) As consumers, what 3 things can we start doing today to become more conscious citizens?

Fashion designer Vivienne Westwood said once: “Buy less, choose well, make it last” and we think, that’s the best fashion rule! One should focus more on classic garments and simple fashion basics, that one can wear all year round without being at the mercy of seasonal fashion trends. Fairly and environmentally friendly produced items may cost more money to purchase than fast fashion, but they pay off in the end – for people and the environment. Therefore, it is better to buy less, but better and more durable quality.

11) By 2030, world leaders have vowed to have made major changes that will positively impact social and environmental concerns: what changes and impacts does Sympatex hope to have achieved by this date?

It is our aim to do not only what is legally necessary but also what is technically possible in order to contribute so that the textile industry can close the ecological cycle as soon as possible. Through our own development and a close dialogue with our customers, we would like to create a clothing industry that combines high individual demands with the uncompromising responsibility for the coming generations.

12) Finally, we would love to hear your thoughts about what you see being the fabric of the future. Will we always be dependent on plastic or do you think there’s a future for more bio based fibres?

“While our main focus remains on closing the textile loop by using our industries’ own waste streams, we will also embrace every other technically feasible opportunity to minimize our footprint by then,” says Dr. Rüdiger Fox, CEO Sympatex Technologies. Our newest development is a membrane with 25% bio-based raw materials, originating from various organic waste streams. This membrane retains its high performance values in terms of breathability as well as water- and windproofness, but also remains fully recyclable at the end of its life cycle. In addition, we are sure, that there will be many other new developments in the next years that will help to reduce emissions and make the next important step in our sustainability journey as well as driving the industry’s transition from conventional to renewable resources.

For more information visit: www.sympatex.com/en/